I2C

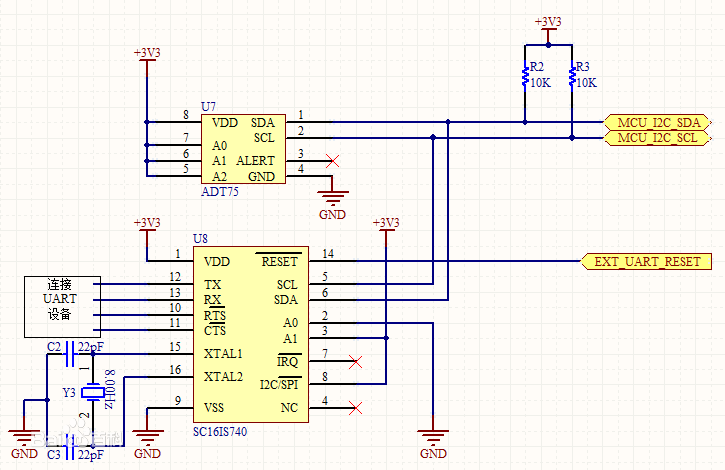

I2C总线是一种简单、双向二线制同步串行总线。SDA(串行数据线)和SCL(串行时钟线)都是双向I/O线,接口电路为开漏输出。需通过上拉电阻接电源VCC.当总线空闲时。两根线都是高电平,连接总线的外同器件都是CMOS器件,输出级也是开漏电路。

MicroPython

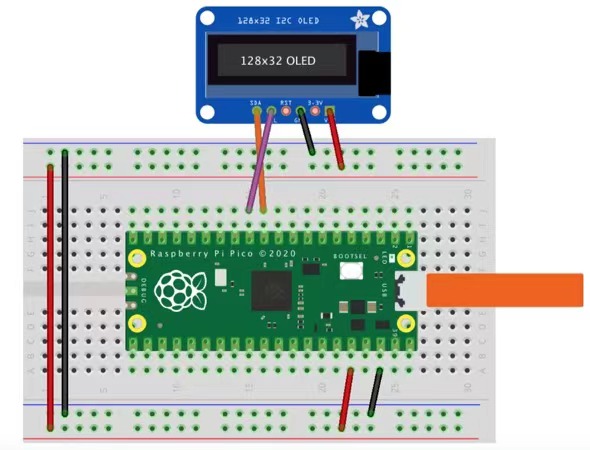

我们以OLED屏幕的通信为例。

from machine import I2C, ADC

from sh1106 import SH1106_I2C

import framebuf

WIDTH = 128 # oled display width

HEIGHT = 128 # oled display height

i2c = I2C(0) # Init I2C using I2C0 defaults, SCL=Pin(GP9), SDA=Pin(GP8), freq=400000

print("I2C Address : "+hex(i2c.scan()[0]).upper()) # Display device address

print("I2C Configuration: "+str(i2c)) # Display I2C config

oled = SH1106_I2C(WIDTH, HEIGHT, i2c) # Init oled display

# Raspberry Pi logo as 32x32 bytearray

buffer = bytearray(b"\x00\x00\x00\x00\x00\x00\x00\x00\x00\x00\x00\x00\x00|?\x00\x01\x86@\x80\x01\x01\x80\x80\x01\x11\x88\x80\x01\x05\xa0\x80\x00\x83\xc1\x00\x00C\xe3\x00\x00~\xfc\x00\x00L'\x00\x00\x9c\x11\x00\x00\xbf\xfd\x00\x00\xe1\x87\x00\x01\xc1\x83\x80\x02A\x82@\x02A\x82@\x02\xc1\xc2@\x02\xf6>\xc0\x01\xfc=\x80\x01\x18\x18\x80\x01\x88\x10\x80\x00\x8c!\x00\x00\x87\xf1\x00\x00\x7f\xf6\x00\x008\x1c\x00\x00\x0c \x00\x00\x03\xc0\x00\x00\x00\x00\x00\x00\x00\x00\x00\x00\x00\x00\x00")

# Load the raspberry pi logo into the framebuffer (the image is 32x32)

fb = framebuf.FrameBuffer(buffer, 32, 32, framebuf.MONO_HLSB)

# Clear the oled display in case it has junk on it.

oled.fill(0)

# Blit the image from the framebuffer to the oled display

oled.blit(fb, 96, 0)

# Add some text

oled.text("Raspberry Pi",5,5)

oled.text("Pico",5,15)

# Finally update the oled display so the image & text is displayed

oled.show()C/C++

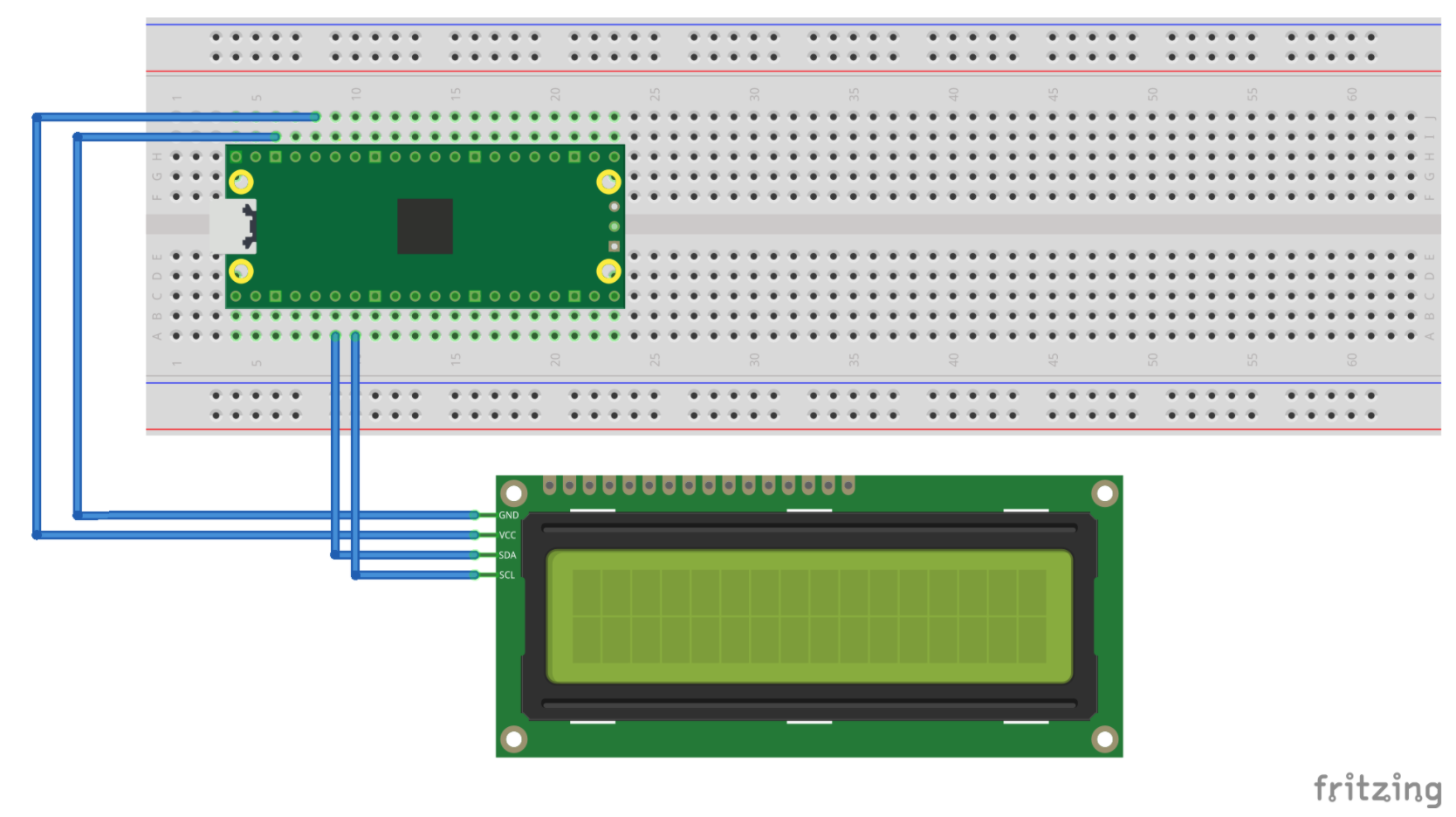

我们以LCD1602为例。

#include <stdio.h>

#include <string.h>

#include "pico/stdlib.h"

#include "hardware/i2c.h"

#include "pico/binary_info.h"

/* Example code to drive a 16x2 LCD panel via a I2C bridge chip (e.g. PCF8574)

NOTE: The panel must be capable of being driven at 3.3v NOT 5v. The Pico

GPIO (and therefor I2C) cannot be used at 5v.

You will need to use a level shifter on the I2C lines if you want to run the

board at 5v.

Connections on Raspberry Pi Pico board, other boards may vary.

GPIO 4 (pin 6)-> SDA on LCD bridge board

GPIO 5 (pin 7)-> SCL on LCD bridge board

3.3v (pin 36) -> VCC on LCD bridge board

GND (pin 38) -> GND on LCD bridge board

*/

// commands

const int LCD_CLEARDISPLAY = 0x01;

const int LCD_RETURNHOME = 0x02;

const int LCD_ENTRYMODESET = 0x04;

const int LCD_DISPLAYCONTROL = 0x08;

const int LCD_CURSORSHIFT = 0x10;

const int LCD_FUNCTIONSET = 0x20;

const int LCD_SETCGRAMADDR = 0x40;

const int LCD_SETDDRAMADDR = 0x80;

// flags for display entry mode

const int LCD_ENTRYSHIFTINCREMENT = 0x01;

const int LCD_ENTRYLEFT = 0x02;

// flags for display and cursor control

const int LCD_BLINKON = 0x01;

const int LCD_CURSORON = 0x02;

const int LCD_DISPLAYON = 0x04;

// flags for display and cursor shift

const int LCD_MOVERIGHT = 0x04;

const int LCD_DISPLAYMOVE = 0x08;

// flags for function set

const int LCD_5x10DOTS = 0x04;

const int LCD_2LINE = 0x08;

const int LCD_8BITMODE = 0x10;

// flag for backlight control

const int LCD_BACKLIGHT = 0x08;

const int LCD_ENABLE_BIT = 0x04;

#define I2C_PORT i2c0

// By default these LCD display drivers are on bus address 0x27

static int addr = 0x27;

// Modes for lcd_send_byte

#define LCD_CHARACTER 1

#define LCD_COMMAND 0

#define MAX_LINES 2

#define MAX_CHARS 16

/* Quick helper function for single byte transfers */

void i2c_write_byte(uint8_t val) {

i2c_write_blocking(I2C_PORT, addr, &val, 1, false);

}

void lcd_toggle_enable(uint8_t val) {

// Toggle enable pin on LCD display

// We cannot do this too quickly or things don't work

#define DELAY_US 600

sleep_us(DELAY_US);

i2c_write_byte(val | LCD_ENABLE_BIT);

sleep_us(DELAY_US);

i2c_write_byte(val & ~LCD_ENABLE_BIT);

sleep_us(DELAY_US);

}

// The display is sent a byte as two separate nibble transfers

void lcd_send_byte(uint8_t val, int mode) {

uint8_t high = mode | (val & 0xF0) | LCD_BACKLIGHT;

uint8_t low = mode | ((val << 4) & 0xF0) | LCD_BACKLIGHT;

i2c_write_byte(high);

lcd_toggle_enable(high);

i2c_write_byte(low);

lcd_toggle_enable(low);

}

void lcd_clear(void) {

lcd_send_byte(LCD_CLEARDISPLAY, LCD_COMMAND);

}

// go to location on LCD

void lcd_set_cursor(int line, int position) {

int val = (line == 0) ? 0x80 + position : 0xC0 + position;

lcd_send_byte(val, LCD_COMMAND);

}

static void inline lcd_char(char val) {

lcd_send_byte(val, LCD_CHARACTER);

}

void lcd_string(const char *s) {

while (*s) {

lcd_char(*s++);

}

}

void lcd_init() {

lcd_send_byte(0x03, LCD_COMMAND);

lcd_send_byte(0x03, LCD_COMMAND);

lcd_send_byte(0x03, LCD_COMMAND);

lcd_send_byte(0x02, LCD_COMMAND);

lcd_send_byte(LCD_ENTRYMODESET | LCD_ENTRYLEFT, LCD_COMMAND);

lcd_send_byte(LCD_FUNCTIONSET | LCD_2LINE, LCD_COMMAND);

lcd_send_byte(LCD_DISPLAYCONTROL | LCD_DISPLAYON, LCD_COMMAND);

lcd_clear();

}

int main() {

// This example will use I2C0 on GPIO4 (SDA) and GPIO5 (SCL)

i2c_init(I2C_PORT, 100 * 1000);

gpio_set_function(4, GPIO_FUNC_I2C);

gpio_set_function(5, GPIO_FUNC_I2C);

gpio_pull_up(4);

gpio_pull_up(5);

// Make the I2C pins available to picotool

bi_decl( bi_2pins_with_func(4, 5, GPIO_FUNC_I2C));

lcd_init();

static uint8_t *message[] =

{

"RP2040 by", "Raspberry Pi",

"A brand new", "microcontroller",

"Twin core M0", "Full C SDK",

"More power in", "your product",

"More beans", "than Heinz!"

};

while (1) {

for (int m = 0; m < sizeof(message) / sizeof(message[0]); m += MAX_LINES) {

for (int line = 0; line < MAX_LINES; line++) {

lcd_set_cursor(line, (MAX_CHARS / 2) - strlen(message[m + line]) / 2);

lcd_string(message[m + line]);

}

sleep_ms(2000);

lcd_clear();

}

}

return 0;

}CMakeList.txt:

add_executable(lcd_1602_i2c

lcd_1602_i2c.c

)

# Pull in our (to be renamed) simple get you started dependencies

target_link_libraries(lcd_1602_i2c pico_stdlib hardware_i2c)

# create map/bin/hex file etc.

pico_add_extra_outputs(lcd_1602_i2c)

# add url via pico_set_program_url

example_auto_set_url(lcd_1602_i2c)SPI

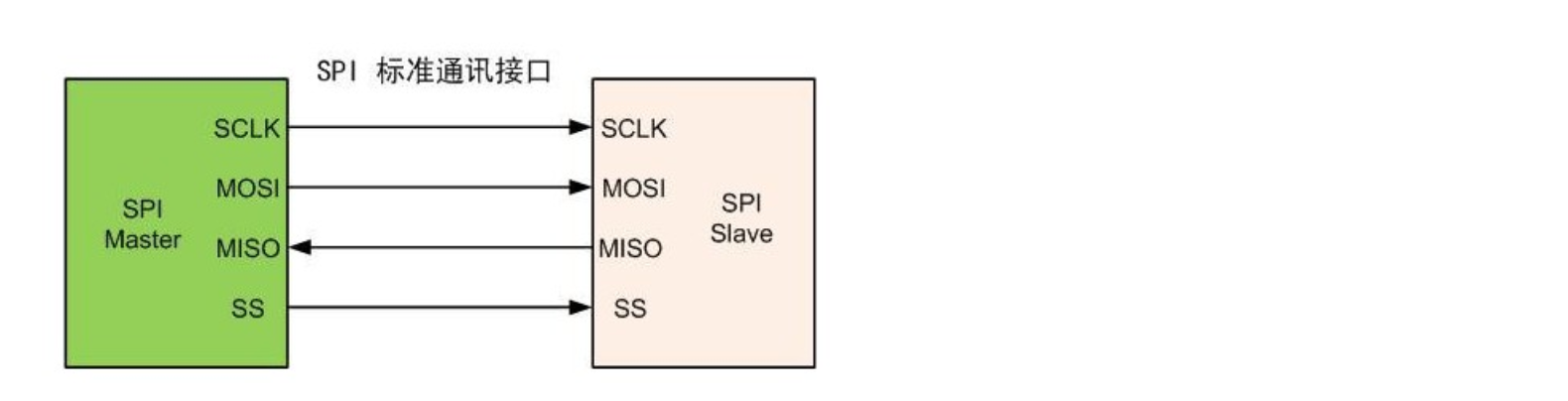

SPI是串行外设接口(Serial Peripheral Interface)的缩写。是 Motorola 公司推出的一 种同步串行接口技术,是一种高速的,全双工,同步的通信总线。主要应用在EEPROM、Flash、实时时钟(RTC)、数模转换器(ADC)、网络控制器、MCU、数字信号处理器(DSP)以及数字信号解码器之间。

MicroPython

from machine import SPI

spi = SPI(0)

spi = SPI(0, 100_000)

spi = SPI(0, 100_000, polarity=1, phase=1)

spi.write('test')

spi.read(5)

buf = bytearray(3)

spi.write_readinto('out', buf)C/C++

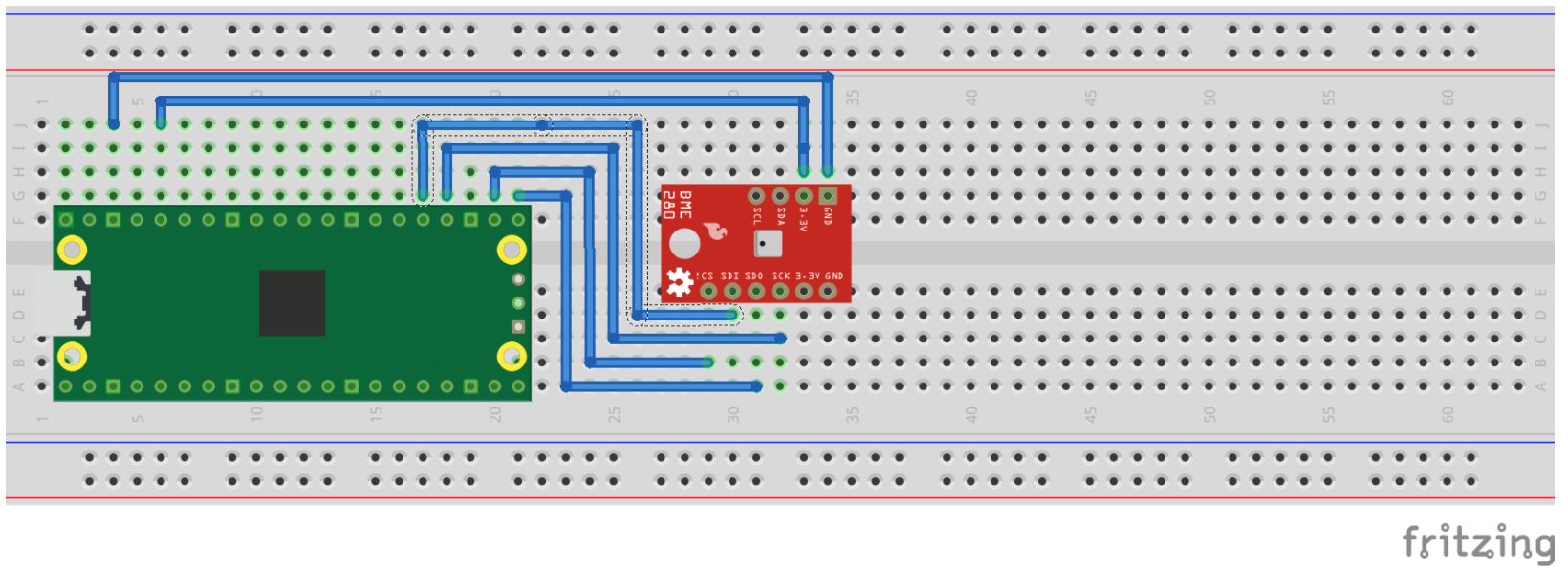

以bme280温度压力传感器为例。

#include <stdio.h>

#include <string.h>

#include "pico/stdlib.h"

#include "hardware/spi.h"

#define PIN_MISO 16

#define PIN_CS 17

#define PIN_SCK 18

#define PIN_MOSI 19

#define SPI_PORT spi0

#define READ_BIT 0x80

int32_t t_fine;

uint16_t dig_T1;

int16_t dig_T2, dig_T3;

uint16_t dig_P1;

int16_t dig_P2, dig_P3, dig_P4, dig_P5, dig_P6, dig_P7, dig_P8, dig_P9;

uint8_t dig_H1, dig_H3;

int8_t dig_H6;

int16_t dig_H2, dig_H4, dig_H5;

/* The following compensation functions are required to convert from the raw ADC

data from the chip to something usable. Each chip has a different set of

compensation parameters stored on the chip at point of manufacture, which are

read from the chip at startup and used inthese routines.

*/

int32_t compensate_temp(int32_t adc_T) {

int32_t var1, var2, T;

var1 = ((((adc_T >> 3) - ((int32_t) dig_T1 << 1))) * ((int32_t) dig_T2)) >> 11;

var2 = (((((adc_T >> 4) - ((int32_t) dig_T1)) * ((adc_T >> 4) - ((int32_t) dig_T1))) >> 12) * ((int32_t) dig_T3))

>> 14;

t_fine = var1 + var2;

T = (t_fine * 5 + 128) >> 8;

return T;

}

uint32_t compensate_pressure(int32_t adc_P) {

int32_t var1, var2;

uint32_t p;

var1 = (((int32_t) t_fine) >> 1) - (int32_t) 64000;

var2 = (((var1 >> 2) * (var1 >> 2)) >> 11) * ((int32_t) dig_P6);

var2 = var2 + ((var1 * ((int32_t) dig_P5)) << 1);

var2 = (var2 >> 2) + (((int32_t) dig_P4) << 16);

var1 = (((dig_P3 * (((var1 >> 2) * (var1 >> 2)) >> 13)) >> 3) + ((((int32_t) dig_P2) * var1) >> 1)) >> 18;

var1 = ((((32768 + var1)) * ((int32_t) dig_P1)) >> 15);

if (var1 == 0)

return 0;

p = (((uint32_t) (((int32_t) 1048576) - adc_P) - (var2 >> 12))) * 3125;

if (p < 0x80000000)

p = (p << 1) / ((uint32_t) var1);

else

p = (p / (uint32_t) var1) * 2;

var1 = (((int32_t) dig_P9) * ((int32_t) (((p >> 3) * (p >> 3)) >> 13))) >> 12;

var2 = (((int32_t) (p >> 2)) * ((int32_t) dig_P8)) >> 13;

p = (uint32_t) ((int32_t) p + ((var1 + var2 + dig_P7) >> 4));

return p;

}

uint32_t compensate_humidity(int32_t adc_H) {

int32_t v_x1_u32r;

v_x1_u32r = (t_fine - ((int32_t) 76800));

v_x1_u32r = (((((adc_H << 14) - (((int32_t) dig_H4) << 20) - (((int32_t) dig_H5) * v_x1_u32r)) +

((int32_t) 16384)) >> 15) * (((((((v_x1_u32r * ((int32_t) dig_H6)) >> 10) * (((v_x1_u32r *

((int32_t) dig_H3))

>> 11) + ((int32_t) 32768))) >> 10) + ((int32_t) 2097152)) *

((int32_t) dig_H2) + 8192) >> 14));

v_x1_u32r = (v_x1_u32r - (((((v_x1_u32r >> 15) * (v_x1_u32r >> 15)) >> 7) * ((int32_t) dig_H1)) >> 4));

v_x1_u32r = (v_x1_u32r < 0 ? 0 : v_x1_u32r);

v_x1_u32r = (v_x1_u32r > 419430400 ? 419430400 : v_x1_u32r);

return (uint32_t) (v_x1_u32r >> 12);

}

static inline void cs_select() {

asm volatile("nop \n nop \n nop");

gpio_put(PIN_CS, 0); // Active low

asm volatile("nop \n nop \n nop");

}

static inline void cs_deselect() {

asm volatile("nop \n nop \n nop");

gpio_put(PIN_CS, 1);

asm volatile("nop \n nop \n nop");

}

static void write_register(uint8_t reg, uint8_t data) {

uint8_t buf[2];

buf[0] = reg & 0x7f; // remove read bit as this is a write

buf[1] = data;

cs_select();

spi_write_blocking(SPI_PORT, buf, 2);

cs_deselect();

sleep_ms(10);

}

static void read_registers(uint8_t reg, uint8_t *buf, uint16_t len) {

// For this particular device, we send the device the register we want to read

// first, then subsequently read from the device. The register is auto incrementing

// so we don't need to keep sending the register we want, just the first.

reg |= READ_BIT;

cs_select();

spi_write_blocking(SPI_PORT, ®, 1);

sleep_ms(10);

spi_read_blocking(SPI_PORT, 0, buf, len);

cs_deselect();

sleep_ms(10);

}

/* This function reads the manufacturing assigned compensation parameters from the device */

void read_compensation_parameters() {

uint8_t buffer[26];

read_registers(0x88, buffer, 24);

dig_T1 = buffer[0] | (buffer[1] << 8);

dig_T2 = buffer[2] | (buffer[3] << 8);

dig_T3 = buffer[4] | (buffer[5] << 8);

dig_P1 = buffer[6] | (buffer[7] << 8);

dig_P2 = buffer[8] | (buffer[9] << 8);

dig_P3 = buffer[10] | (buffer[11] << 8);

dig_P4 = buffer[12] | (buffer[13] << 8);

dig_P5 = buffer[14] | (buffer[15] << 8);

dig_P6 = buffer[16] | (buffer[17] << 8);

dig_P7 = buffer[18] | (buffer[19] << 8);

dig_P8 = buffer[20] | (buffer[21] << 8);

dig_P9 = buffer[22] | (buffer[23] << 8);

dig_H1 = buffer[25];

read_registers(0xE1, buffer, 8);

dig_H2 = buffer[0] | (buffer[1] << 8);

dig_H3 = (int8_t) buffer[2];

dig_H4 = buffer[3] << 4 | (buffer[4] & 0xf);

dig_H5 = (buffer[5] >> 4) | (buffer[6] << 4);

dig_H6 = (int8_t) buffer[7];

}

static void bme280_read_raw(int32_t *humidity, int32_t *pressure, int32_t *temperature) {

uint8_t buffer[8];

read_registers(0xF7, buffer, 8);

*pressure = ((uint32_t) buffer[0] << 12) | ((uint32_t) buffer[1] << 4) | (buffer[2] >> 4);

*temperature = ((uint32_t) buffer[3] << 12) | ((uint32_t) buffer[4] << 4) | (buffer[5] >> 4);

*humidity = (uint32_t) buffer[6] << 8 | buffer[7];

}

int main() {

stdio_init_all();

printf("Hello, bme280! Reading raw data from registers via SPI...\n");

// This example will use SPI0 at 0.5MHz.

spi_init(SPI_PORT, 500 * 1000);

gpio_set_function(PIN_MISO, GPIO_FUNC_SPI);

gpio_set_function(PIN_SCK, GPIO_FUNC_SPI);

gpio_set_function(PIN_MOSI, GPIO_FUNC_SPI);

// Chip select is active-low, so we'll initialise it to a driven-high state

gpio_init(PIN_CS);

gpio_set_dir(PIN_CS, GPIO_OUT);

gpio_put(PIN_CS, 1);

// See if SPI is working - interrograte the device for its I2C ID number, should be 0x60

uint8_t id;

read_registers(0xD0, &id, 1);

printf("Chip ID is 0x%x\n", id);

read_compensation_parameters();

write_register(0xF2, 0x1); // Humidity oversampling register - going for x1

write_register(0xF4, 0x27);// Set rest of oversampling modes and run mode to normal

int32_t humidity, pressure, temperature;

while (1) {

bme280_read_raw(&humidity, &pressure, &temperature);

// These are the raw numbers from the chip, so we need to run through the

// compensations to get human understandable numbers

pressure = compensate_pressure(pressure);

temperature = compensate_temp(temperature);

humidity = compensate_humidity(humidity);

printf("Humidity = %.2f%%\n", humidity / 1024.0);

printf("Pressure = %dPa\n", pressure);

printf("Temp. = %.2fC\n", temperature / 100.0);

sleep_ms(1000);

}

return 0;

}CMakeList.txt:

add_executable(bme280_spi

bme280_spi.c

)

# Pull in our (to be renamed) simple get you started dependencies

target_link_libraries(bme280_spi pico_stdlib hardware_spi)

# create map/bin/hex file etc.

pico_add_extra_outputs(bme280_spi)

# add url via pico_set_program_url

example_auto_set_url(bme280_spi)本文转自:Github

作者:zihan987

推荐阅读

- 阿chai带你学Raspberry Pi Pico基础篇:IO口的使用/UART通信/中断/定时器

- 阿chai带你学Raspberry Pi Pico:环境搭建与简介

- 华为A910芯片+MindSpore与2080Ti/P100/T4+PyTorch实测对比

更多嵌入式AI技术相关内容请关注嵌入式AI专栏。